PVC-O pipes are the best choice for high pressure pipe (piping) to be used for water conveyance. The latest technology PVC-O pipes have considerable advantages over the conventional pipes such as Ductile Iron pipe and HDPE pipes. The PVC-O pipes are easy in handling and laying compared to DI pipes and HDPE pipes. No heavy machineries or welding is required. The manufacturing of PVC-O pipes is the most eco friendly amongst all the high pressure pipe manufacturers. Finally, it’s a food grade, green product. PVC is an amorphous polymer in which the molecules are arranged randomly. Under certain conditions of pressure, temperature and speed, by stretching, it is possible to orient the polymer molecules in the same direction as which the material has been stretched. Depending on the various process parameters and mainly stretch ratio, a higher or lower orientation degree is obtained. The result is plastic with a layered structure. The molecular orientation converts the amorphous structure into a layered structure. The layered structure gives the pipes desirable qualities such as pipe pressure withstanding capacity, lower wall thickness, zero crack propagation, resistance to traction and fatigue, flexibility, excellent response to water hammer and high impact resistance. The pressure ratings available are PN12.5, PN16, PN20 and PN25. The pipes are manufactured as per BIS standard IS 16647:2017. Our pipes have been used for various lift irrigation projects, pressurised water conveyance and water infrastructure projects in various Government departments. The various advantages of plastic pipes such as non-corrosive and the strength of metal pipes is combined here in oriented PVC (PVC-O) pipes. We have all the required PVC-O fittings to support a PVC-O piping system. The various PVC-O fittings available include 45° Elbows, 22.5° Elbows, 11.25° Elbows, sliding coupler, reducer, etc. All types of fittings required for a project including Tees and Flanges are also supplied as per customer requirement. Molecular Orientation reduces the pipe wall thickness, giving a greater internal diameter and flow section. Also, the internal surface of PVC-O Pipes is extremely smooth, reducing load loss and making it more difficult for deposits to be formed on the inner wall. This leads to 15-40% more hydraulic capacity than other pipes with the same external diameter. The quality of fluid that flows through the pipes always remains unaltered, given that PVC-O material neither suffers corrosion nor migration within the pipes. It is considered as the best application for high-pressure water transport, particularly drinking water, for water supply networks. PVC-O Pipes are lighter and easier to handle than other pipes and, in most cases, does not require machinery even for higher dimensions. Smooth and thinner wall results in higher amount of water flow and upto 30% savings in electricity cost. There is a positive stand out in terms of cost, performance and installation speed compared to other pipes. Immune to Corrosion and natural chemicals as well as micro and macro organisms, CCAL PVC-O pipes are not degradable. Also, no special protection or coating is required, thereby saving cost. Pipes are easy to join and can be installed by semi – skilled workers. 100% water-tight joints are guaranteed and do not displace once installed. PVC-O is the best solution for medium and high-pressure water networks for irrigation systems, potable water supply and pumping systems, among other applications.

CCAL manufactures PVC-O Pipes in two pressure classes, namely PN12.5 (12.5 kg/cm2) and PN16 (16 kg/cm2). The pipes are manufactured in six diameters suitable for Indian topography: Nominal Diameter (DN) 110mm (4”), 160mm (6”), 200mm (8”), 250mm (10”), 315mm (12”) and 400mm (16”).

| |

Outside Diameter (OD) |

PN12.5 |

PN16 |

| Nominal Diameter (DN) |

Min |

Max |

Inside Diameter (ID) |

Wall Thickness (e) |

Inside Diameter (ID) |

Wall Thickness (e) |

| Mm |

|

|

Average |

Min |

Average |

min |

| 110 |

110.0 |

110.4 |

104.4 |

2.4 |

104.0 |

2.4 |

| 160 |

160.0 |

160.5 |

152.0 |

3.5 |

151.4 |

3.5 |

| 200 |

200.0 |

200.6 |

190.0 |

4.3 |

189.2 |

4.4 |

| 250 |

250.0 |

250.8 |

237.4 |

5.4 |

236.4 |

5.5 |

| 315 |

315.0 |

316.0 |

299.2 |

6.8 |

298.0 |

6.9 |

| 400 |

400.0 |

401.2 |

379.8 |

8.7 |

378.4 |

8.8 |

All ranges of PVC-O Fittings are available: 11.25° PN16 bar Bend, 22.5° PN16 bar Bend, 45° PN16 bar Bend, PN16 bar Reducer, PN16 bar Coupler, PN16 bar Repair Coupler.

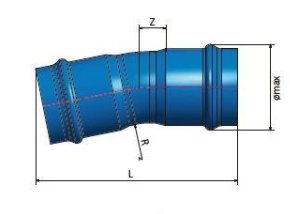

11,25° PN16 bar bend

| DN |

Reference |

∅max |

L(mm) |

Z(mm) |

Radius(mm) |

| 110 |

F110C1116B |

140 |

455 |

55 |

165 |

| 160 |

F160C1116B |

200 |

535 |

70 |

240 |

| 200 |

F200C1116B |

245 |

595 |

80 |

300 |

| 250 |

F250C1116B |

305 |

690 |

95 |

375 |

| 315 |

F315C1116B |

375 |

790 |

115 |

475 |

| 400 |

F400C1116B |

475 |

925 |

140 |

600 |

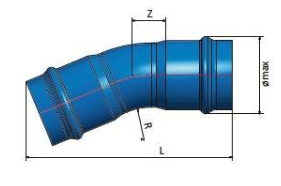

22,5° PN16 bar bend

| DN |

Reference |

∅max |

L(mm) |

Z(mm) |

Radius(mm) |

| 110 |

F110C2216B |

140 |

490 |

70 |

165 |

| 160 |

F160C2216B |

200 |

585 |

95 |

240 |

| 200 |

F200C2216B |

245 |

655 |

110 |

300 |

| 250 |

F250C2216B |

305 |

765 |

135 |

375 |

| 315 |

F315C2216B |

375 |

885 |

160 |

475 |

| 400 |

F400C2216B |

475 |

1045 |

200 |

600 |

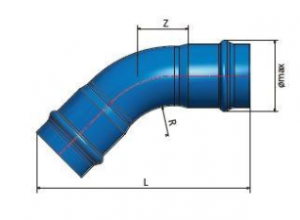

45° PN16 bar bend

| DN |

Reference |

∅max |

L(mm) |

Z(mm) |

Radius(mm) |

| 110 |

F110C4516B |

140 |

555 |

105 |

165 |

| 160 |

F160C4516B |

200 |

680 |

145 |

240 |

| 200 |

F200C4516B |

245 |

770 |

175 |

300 |

| 250 |

F250C4516B |

305 |

910 |

215 |

375 |

| 315 |

F315C4516B |

375 |

1070 |

265 |

475 |

| 400 |

F400C4516B |

475 |

1280 |

330 |

600 |

PN16 bar Reducer

| DN |

Reference |

∅max |

L(mm) |

Z(mm) |

| 110/90 |

F110R09016B |

140 |

390 |

60 |

| 160/110 |

F160R11016B |

200 |

485 |

110 |

| 160/140 |

F160R14016B |

200 |

460 |

65 |

| 200/160 |

F200R16016B |

245 |

530 |

105 |

| 250/200 |

F250R20016B |

305 |

600 |

130 |

| 315/250 |

F315R25016B |

375 |

695 |

165 |

| 400/250 |

F400R25016B |

475 |

860 |

290 |

| 400/315 |

F400R31516B |

475 |

810 |

200 |

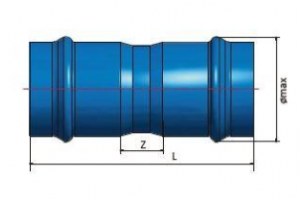

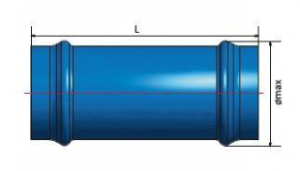

PN16 bar Coupler

| DN |

Reference |

∅max |

L(mm) |

Z(mm) |

| 110 |

F110M16B |

140 |

425 |

80 |

| 160 |

F160M16B |

200 |

495 |

90 |

| 200 |

F200M16B |

245 |

535 |

100 |

| 250 |

F250M16B |

305 |

630 |

125 |

| 315 |

F315M16B |

375 |

720 |

155 |

| 400 |

F400M16B |

475 |

850 |

195 |

PN16 bar Repair Coupler

| DN |

Reference |

∅max |

L(mm) |

Z(mm) |

| 110 |

F110MR16B |

140 |

425 |

– |

| 160 |

F160MR16B |

200 |

495 |

– |

| 200 |

F200MR16B |

245 |

535 |

– |

| 250 |

F250MR16B |

305 |

630 |

– |

| 315 |

F315MR16B |

375 |

720 |

– |

| 400 |

F400MR16B |

475 |

850 |

– |