CCAL uses a continuous sequential two-stage extrusion process to produce PVC-O pipes. The PVC-O plant uses the following process.

CCAL uses a continuous sequential two-stage extrusion process to produce PVC-O pipes. The PVC-O plant uses the following process.

In the first stage, the PVC compound is plasticised, homogenised and shaped into a pipe. This is followed by the orientation process, wherein the orientation of the molecular structure of the O-PVC pipes is changed under pre-programmed temperature conditions.

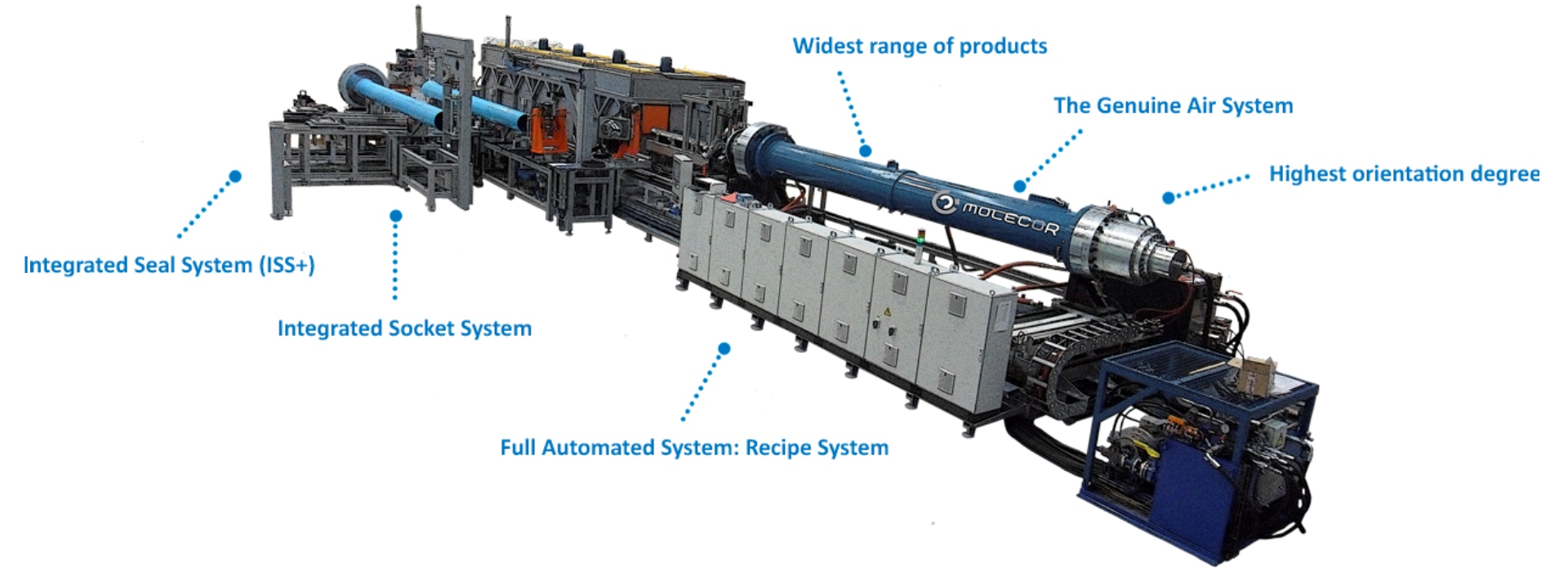

CCAL procured the machines required for the manufacture of these pipes from M/s Molecor Tech, Spain. Molecor, the world leader in extrusion technology, supplied both the technology and the extrusion line.

The major raw material required in the manufacturing process is PVC resin. We source this resin from indigenous sources as well as via imports.

We produce pipes of sizes ranging from 110mm to 400mm in diameter at our PVC-O plant in Sri City. Once the pipes are manufactured, they are palletised, stocked, and dispatched to distributors and clients in trucks and trailers.

These pipes are used in high-pressure water delivery applications. PVC-O pipes are a good substitute for Ductile Iron (DI) pipes.

The best mechanical properties

Tensile Resistance

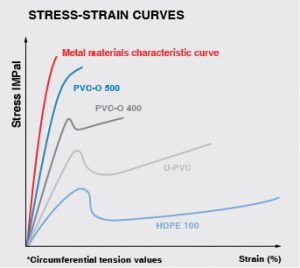

In terms of resistance, PVC-O shows a very different stress-strain curve when compared with conventional plastics and comes very close to the curve of metals.

In terms of resistance, PVC-O shows a very different stress-strain curve when compared with conventional plastics and comes very close to the curve of metals.

Mechanical properties complete transformation of PVC-O compared to conventional PVC can only be achieved in the higher class PVC-O class 500 such as TOM pipes.